T-Shirt Printing

10-minute video

Laser light printing for white and light-colored shirts

9:30 minute video

Laser dark printing for black and dark-colored shirts

11:46 minute video

HTV printing for any color of shirt

4-minute video

Sublimation printing for polyester shirts ONLY

Preparation

Get the T-shirt you’d like to print on, preferably cotton or other natural materials for best results. Synthetics will work best with sublimation printing (link to sublimation printing). Next, find or make a design you’d like to put on your shirt. Save this file as a .PDF scaled to 8.5x11 inches so your image does not get distorted. The program will accept .PNG and .JPG but will auto scale them.

Loading your file

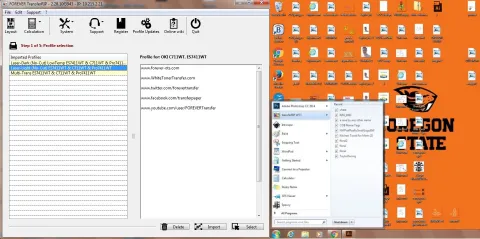

Load your file onto the T-Shirt printing computer and open transferRIP WTT. From here choose either Laser-Dark (dark fabrics) or Laser-Light (light fabrics, usually white), then click select.

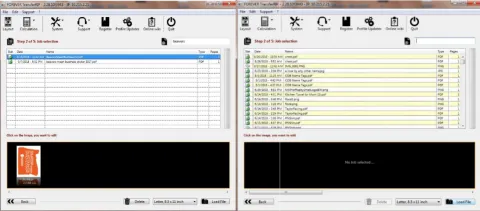

Hit the load button to load your file, allow the program to load it, choose that file from the list of files in the list, and then allow it to render a preview.

Click on this preview and follow steps that the program provides. Avoid changing the settings unless needed or with staff suggestion. Do not hit the print button at this point, instead continue to the step below.

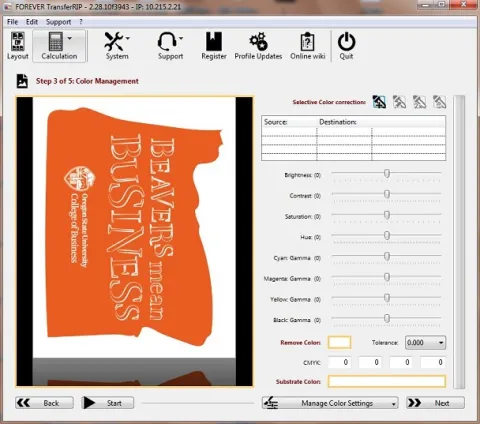

When printing an image that has a large surface area, use the Micro Mask setting and set the percentage from 2%-6%. If an image is smaller or is mostly empty space, use the "Screening from Printer" setting.

Setting up the printer

Load the T-shirt printer with only one sheet of the correct paper based on the material and color of your fabric. For laser light, use laser light paper. For dark shirts, use laser dark paper.

For designs with black

The C332 (Ringo) has black ink and should be used for printing black designs on a light T-Shirt.

For designs with white

The OKI C711WT (Paul) has white ink and therefore should be used when printing designs with white for a dark T-Shirt.

Printing

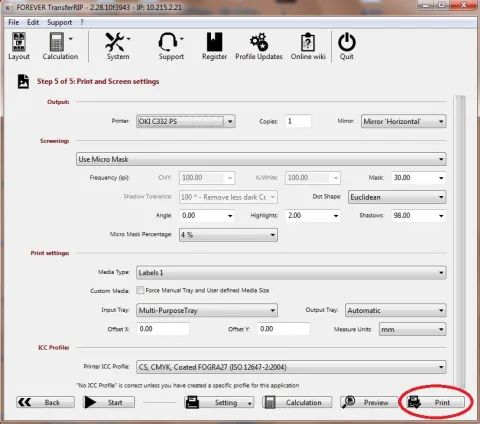

After loading the correct printer with the corresponding printing paper, turn on the printer (if it’s not already on). Back in transferRIP, select your printer on the bottom of the program, then click the print button. To print multiple shirts at once, change the copy amount, but still only load one piece of paper at a time. Click print, and wait for the printer to show “On Line”. Click the green online button on the printer, and wait for your design to print. Great job, you’ve made it past the hard part.

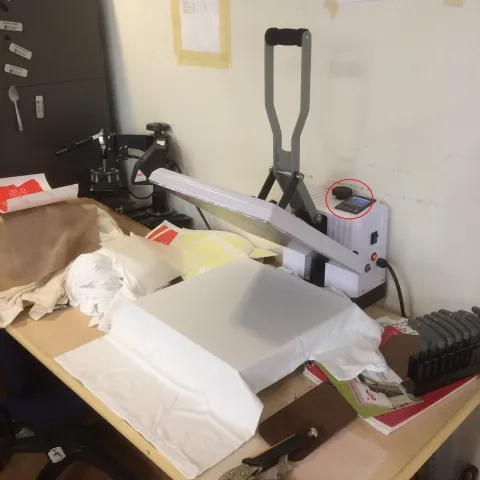

Using The Heat Press

Turn on the press, enter the time and temperature values needed for your fabric, and then allow the press to heat up. While the press is heating up, make sure that you have all your specs correct, including how much pressure to apply to the shirt. This can be adjusted by the knob just left of the control panel on the heat press.

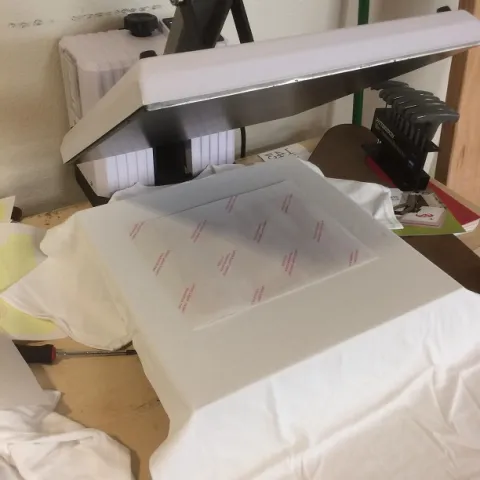

Starting the transfer

Once your press has reached temp, use it as a traditional ironing board by removing any creases from your fabric. Do this only for a few seconds, just enough to remove the creases but not enough to overheat the shirt. Place your design face down, where you want it on the fabric. Press the heat press down firmly until it clamps in place, wait for the timer to run out.

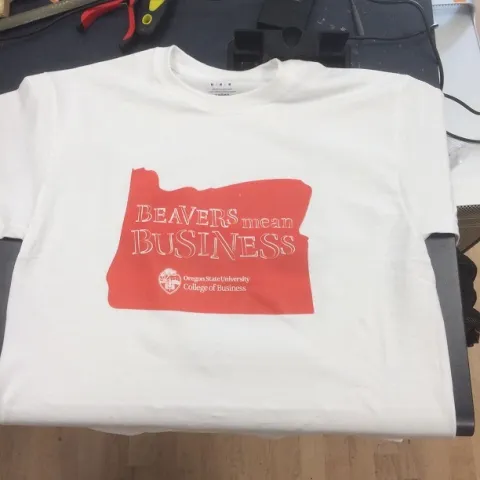

Finishing the transfer

When the time runs out, quickly release the material. Count for 5-10 seconds, then smoothly and quickly remove the paper from the shirt. Stretch your design while the fabric is still hot to ensure durability in the future. Cover your design with the white sealing paper, and press for 15-20 seconds. Finally, open the press, peel the paper off, and remove your shirt from the heat press.

Cleaning up

Please remember to turn off the heat press when you are finished, unless there is a group just about to use it. If they will take more than five minutes to use the press, they can turn it on when they are ready. Clean up all paper that was used.